Why was the sway bar link invented?

- Share

- Issue Time

- Dec 15,2025

The sway bar link (also known as an anti-roll bar link or stabilizer bar link) was invented to address a key engineering requirement: establishing a reliable, flexible, and efficient force-transfer connection between the moving components of a suspension system.

Specifically, its invention was primarily driven by the following reasons:

To Enable Force Transmission Path

Core Function: The sway bar itself is a torsion bar fixed to the chassis or subframe. To function, it must "transmit" the vertical motion of the wheel suspension to the bar, causing it to twist. The sway bar link serves as the "bridge" connecting the moving component (the wheel-side suspension, such as the shock absorber or control arm) and the relatively fixed component (the end of the sway bar). Without it, the sway bar cannot sense the wheel's motion and would be rendered ineffective.

To Accommodate Complex Suspension Movements

Motion Compensation: When a vehicle is in motion, the wheels not only move vertically but also follow a curved trajectory. At the same time, the sway bar may shift slightly under force. A simple rigid connection would cause interference, noise, or component damage.

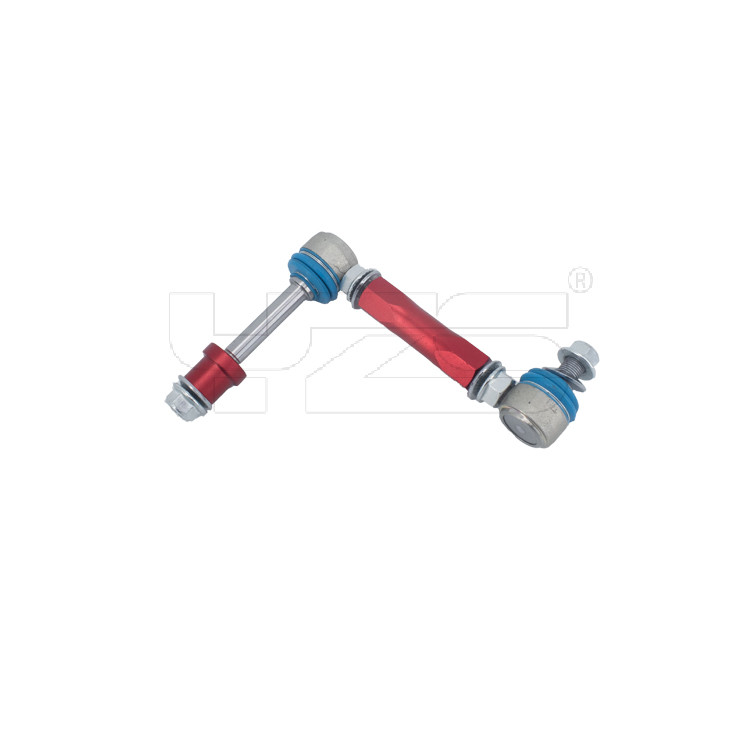

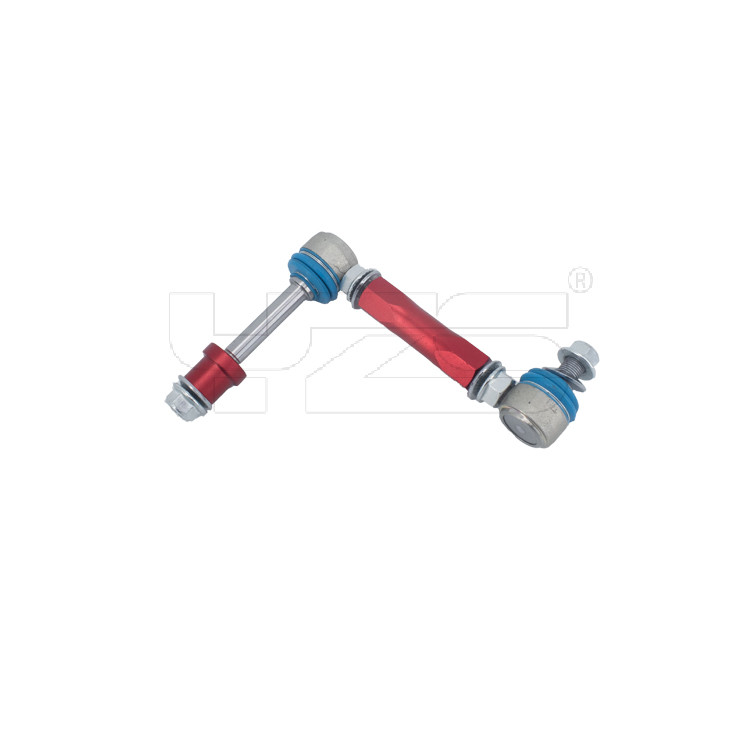

Solution: The sway bar link is equipped with ball joints or elastic bushings at both ends, creating a "universal joint" type of connection. This allows it to flexibly pivot in multiple directions, perfectly compensating for the complex relative motion between the suspension and the sway bar, ensuring smooth force transmission without binding stress.

To Enhance Durability and Maintainability

Stress Concentration Point: The connection point is a critical area for force transmission, enduring significant alternating stress. Designing it as an independent, replaceable link component exemplifies excellent engineering modularity.

Ease of Replacement: Compared to welding the sway bar directly or using complex structural connections, an independent link can be replaced individually, quickly, and at low cost after wear or damage (common failures include loose ball joints or torn bushings). This avoids the need to disassemble the suspension or the main sway bar, significantly reducing maintenance costs.

To Provide Flexibility for Tuning and Adaptation

Adjustable Length: In some high-performance or aftermarket applications, the link length is adjustable. This allows technicians to fine-tune the preload of the sway bar, precisely influencing the vehicle's handling balance (such as altering understeer or oversteer characteristics).

Universal Adaptation: The same sway bar can be adapted to different vehicle models or suspension heights (e.g., after lowering the vehicle) by using links of varying lengths or angles.

In summary, the invention of the sway bar link was an inevitable outcome of "specialization" and "modularization" in suspension engineering. It was created as a dedicated, flexible, and maintainable connector with the core purpose of:

Efficiently and reliably converting the suspension movement of the wheels into torsional force on the sway bar, thereby suppressing body roll while adapting to real-world complex motions and facilitating manufacturing, maintenance, and performance tuning. Without it, the sway bar in modern independent suspension systems would not be practical.